Prototype manufacturing has helped many manufacturers to evaluate the viability of their ideas and the end-user experience of a specific solution.

What is custom prototyping?

Custom prototyping is the on-demand manufacturing of incomplete versions of a proposed solution. The incomplete version may sound bad, but then the main objective of prototype development is to simulate only a few main aspects of the concept. This helps the users to evaluate the viability of potential solution in terms of usually, cost, complexity and value. Customer prototyping also enable the clients to visually see their product before manufacturing and serve as a concept proof to the stakeholders.

Rapid Prototyping and design thinking

Design thinking as a mindset is the methodology used by the manufacturer for crafting prop types to the complex problems and design challenges faced by the client. Rapid prototyping and design thinking go hand in hand. Visual representation of the prototype along with its evaluation, understanding and learning from ideas are at the core of design thinking.

Therefore, the prototype manufacturers need to be creative and talented enough to suggest the clients with different designs options. Also they need have a dedicated team of designers that are ever ready to help their clients with their design related confusions and queries.

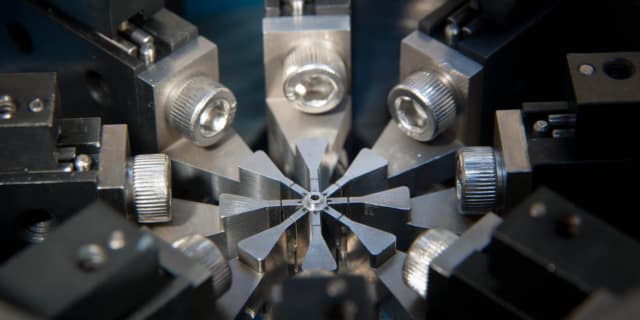

Why rapid CNC prototyping and what are its advantages

CNC prototyping in the custom prototyping market is one of the most common rapid protoytping technique used by the manufacturer across the globe and there are several reasons for that;

- Early user acceptance testing

People and the clients get a chance to experience and use the product before it is put into the production line. This results in a proof of concept to many along with the stakeholders. Getting your custom prototype done also result in an early feedback pool from the user base and see if their ideas and concepts are worth full production.

- Better time, cost and complexity estimates

With the prototype development, the clients and the manufacturers can realise the additional requirements along with the constraints early in the product development phase. Also, by receiving the user feedback early, the manufacturer can make better estimates for the complexity of the production as well as the time needed for the product to be produced. Prototyping also saves the clients with unexpected expenses due to flawed designs or wrong material selection.

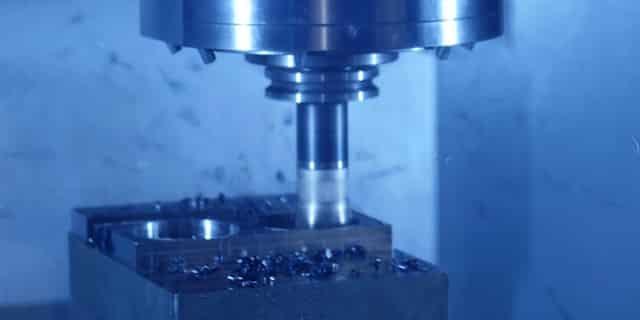

Rapid prototyping of an aluminum block

- Realise constraints and requirements that were not previously considered

By effectively simulating the functionality of the product via prototype machining, the manufacturing team or the designers may discover additional requirements that were previously hidden or not considered at all. This greatly assists in achieving a more robust and complete solution.

Disadvantages of CNC rapid prototyping

Though the CNC prototyping has big advantages, there are some disadvantages which are discussed as follows;

- Insufficient analysis

The confidence of a great prototype can put the team to abandon further analysis of features. This could at time result in part of the product to be well-designed while the remaining parts to be left incomplete or vague.

- User confusion may arise

If the final product look or function different than the original prototype, the end users may be confused about how it operates and may also reject the final product.

- Expense of prototyping

Although prototyping saves the cost of the product in the actual development phase, there are costs induced in doing the prototyping itself. For this reason, it is said that your prototype manufacturer must be excellent and must offer the service at low rates.

The risk of spending money on a prototype that could potentially be thrown must be fully understood. It must be noted that the prototype is still a valuable and much-needed phase of product development. Despite some of its development drawbacks, the advantages are significantly huge.

Several stages of prototype development

Creating your custom prototype takes several stages in the background which are discussed as follows;

- Creating bill of materials (BOM)

BOM is the list of all the materials that goes into the manufacturing of the prototype. By creating the BOM, the manufacturer and the client both have a clear idea of what goes into the production.

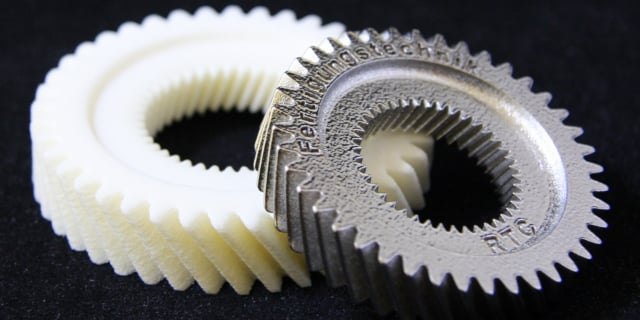

- Technical development

The second thing to do while making the prototype is to create a piece that works as to fulfil your vision. Under this phase of development, the product is made to ‘work like a prototype’. It is not the final product, but a visual representation of how your product will look like once it goes into full production.

- Design for manufacture

Once the previous designs and visual prototypes are approved, the prototypes are designed for last manufacturing stage. The testing and design engineers make sure that the manufacturing prototype looks exactly as per the client requirements as the prototype confirmed at this stage will go into full production and will have no further reviews.

- Final production

Once everything is finalized and the funding is completed, rapid manufacturing takes place and the finished products off the assembly lines are delivered to the clients.

Why china prototyping wins?

If you have decided to get your prototyping done and is looking for an excellent custom prototype manufacturer or a rapid manufacturing company, all your findings will lead to China. China prototype manufacturing industry is on the boom today, and it is because of the high investment and interest shown by the government to support this market. Most rapid manufacturing companies have strong production capacity and advanced 5-Axis CNC machining equipment etc.

In the international market, rapid prototyping China are global leaders. Let it be CNC prototyping or CNC rapid prototyping; china prototype manufacturing is dominating the international market. They offer competitive pricing at excellent results. China also excels in hiring experienced workers and dedicated labors at cheap rates making the finished products to be cheaper and better than the manufacturers in other markets.

In future, any Chinese prototype manufacturers want to participate in international markets, they must add more competition and excellence in the prototype manufacturing industry of China by delivering great prototypes via its state-of-the-art machines, experienced operators and ever supportive people looking to cater to your prototyping needs. Finally, make every ideas of globe customers turn into reality.