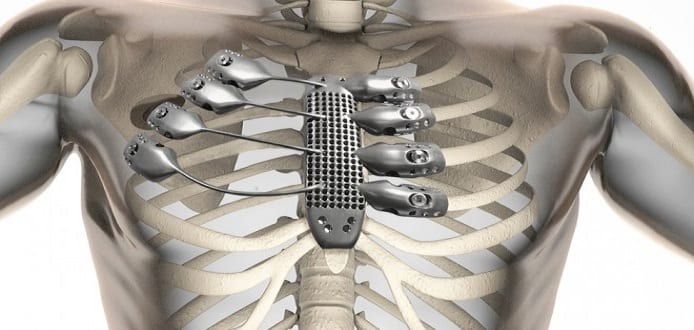

3D-printed titanium sternum and rib cage implanted in a cancer patient

Looks like 3D printing has just gone one notch higher. Lab 22 at Australia’s CSIRO that has a growing list of 3D-printed medical implants right from a 3D-printed mouth guard for sleep apnea sufferers, to a 3D-printed heel bone, to the world’s first 3D-printed jet engine, had added one more feather to its cap.

A 54-year-old Spanish man, who had a cancerous tumor, was recently fitted with a 3D printed titanium sternum and rib cage, which is the first surgical operation of its kind. He was detected with chest wall sarcoma, a cancerous tumor that grows in the chest wall, and in this case, had grown around his sternum and part of his rib cage. To remove the tumor completely, surgeons also had to excise that part of his skeleton.

The sternum and rib cage also is complex, and difficult to replicate. Normally, in cases like these, a flat titanium plate is used to support the structure of the rib cage. However, these are not an excellent option, as they loosen over a period of time, and increase the risk of complications.

Therefore, for this reason, the patient’s surgical team at Salamanca University Hospital in Salamanca, Spain, instructed Melbourne, Australia-based medical device company Anatomics to create a customizable 3D titanium implant using high resolution CT scans that could replicate the complicated structure of the sternum and rib cage and fit perfectly in the patient’s chest. It also allowed Anatomics to create an accurate implant that would match the excision, as well as the individual size and shape of the patient’s chest.

Next, the 3D digital CAD file detailing the patient’s anatomy was sent to Lab 22 to build the customized implant, who then used the Arcam’s AUD$1.3 million electron beam metal printer to print the implant layer-by-layer.

“The advantage of 3D printing is its rapid prototyping,” Adam Knight of CSRIO, a government scientific research agency in Australia that offered its lab for the printing wrote in a blog post. “When you’re waiting for life-saving surgery this is the definitely the order of the day.”

The printed metal implant, which can go over the bones on one side and be screwed on securely on the other side, was shipped to Salamanca University Hospital soon after it was ready. The surgery was a success and the patient with the titanium rib cage is reportedly on his way to recovery. He was discharged from the hospital 12 days after the surgery.

Watch the video below that explains the process used to create the implant.